The President of the Steel Strip Society Ing. Martin Špok opened the plenary part of the seminar at 9:00 a.m. on April 23, 2024. He first welcomed everyone present in the conference room of the Wellness Hotel Diana, Velké Losiny. Also the guarantors of the seminar Ing. Tomáš Barták, UVB Technician and Ing. Daniel Hajduk, Ph.D., ITA, welcomed everyone present.

The plenary agreed without comments to the following program of the plenary session:

- Opening of the 90th working seminar

- Acquaintance with the program of the 90th workshop, control of participation

- Evaluation of the 89th workshop

- Information on the activities of the executive board for the last period since the 89th working seminar

- Report on the management of the Company for the year 2023

- Draft budget for 2024

- Audit Report

- Preparation of the 91st autumn seminar

- Changes in membership

- Discussion and misc

- Information on the SOP executive board elections

- Break

- SOP Executive Board Elections

- Organizational instructions for other parts of the seminar

The working part of the 90th workshop took place on 23 April 2024 in the afternoon, in the conference room of the Wellness Hotel Diana. Seminar guarantors Ing. Tomáš Barták and Ing. Daniel Hajduk, Ph.D., opened the afternoon lecture block, during which the following lectures were presented:

1. Transverse profile and flatness

Ing. Daniel Hajduk, Ph.D., ITA

2. Computer simulation of hot-rolled products cooling

Ing. Pavel Šimeček, Ph.D., ITA

3. Scraping and degreasing equipment UVB TECHNIK in the production of metal strips

Ing. Pavel Vitoslavský, UVB Technik

4. Metallurgical rollers – shape, grinding, service life

Ing. Daniel Hajduk, Ph.D., ITA

The members of the Society asked professional questions about individual lectures, which were always satisfactorily answered by the lecturers.

The social evening took place in the restaurant of the Wellness Hotel Diana.

Although there were no life anniversaries at this seminar, we celebrated the reception of new members from the previous and this seminar.

As is already a good practice at the seminars of the Society of Steel Belts, the evening was accompanied by fruitful, informal conversation between guests and members.

The traditional excursion took place on Wednesday 24 April 2024 at AL INVEST Břidličná a.s.

The company structure itself is divided into two production divisions, the Aluminum division and the Packaging division.

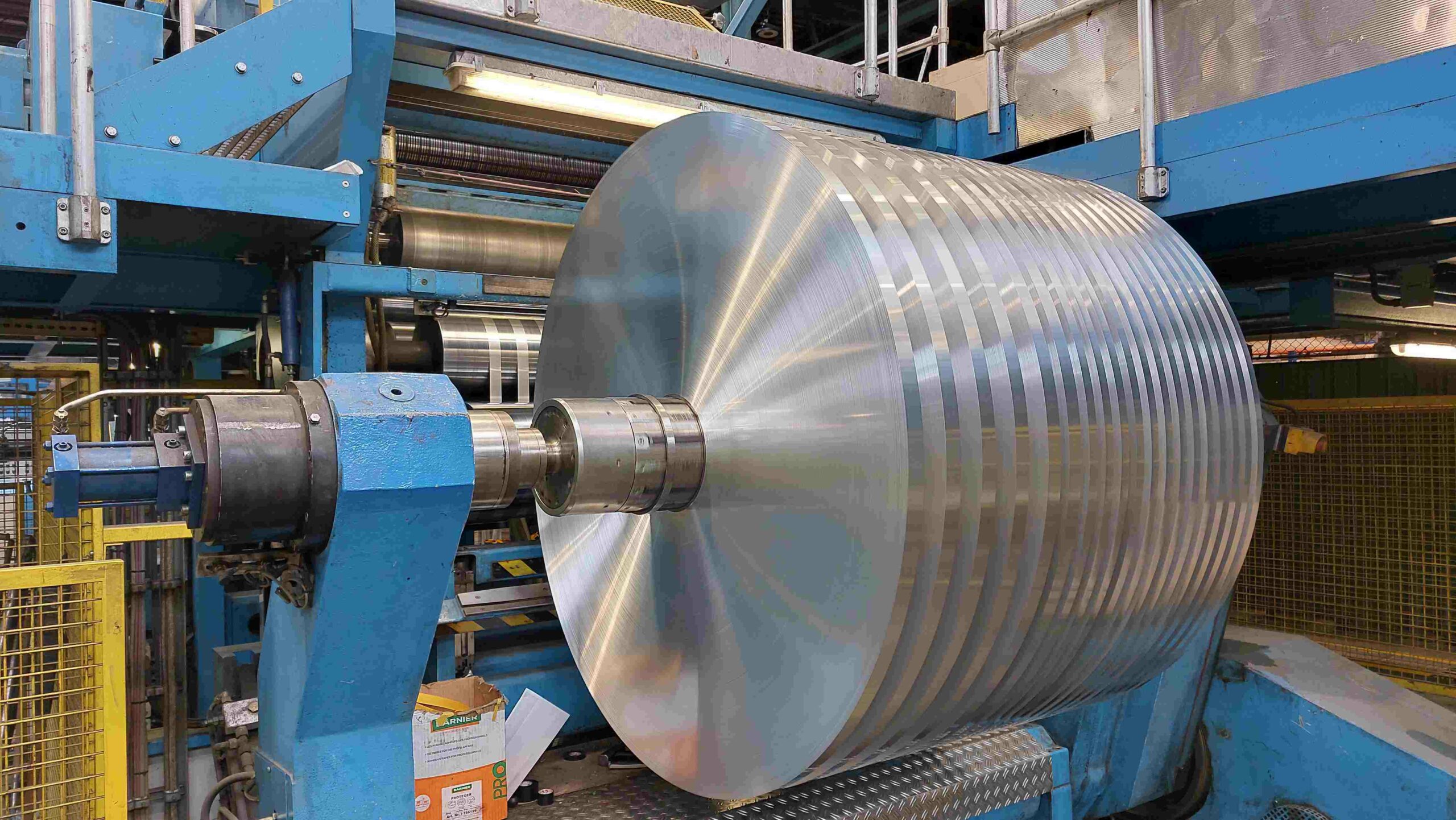

We visited the Aluminum division. We toured the Plate Melter, the T9 remelting furnace, the DUO 800 hot rolling mill, and plate cutting and milling. These are then largely processed into roasts and used in the automotive industry to produce fuel tanks.

Next, we saw the smelter contility and the casting aggregate of the aluminum strip, which is then wound into a coil. These coils are then cold-rolled on rolling mills quarto 1400 or KVARTO 1 to 4 into thin strips and foils several micrometers thick. Furthermore, they are annealed by homogenization or recrystallization. They are then divided into the required size on the dividing lines.

The Packaging division processes foil for use in the food industry, pharmaceuticals, tobacco, insulation and technical applications. For this, it uses Refinery I (Flexo printing machine BHS, Gravure printing machine BOBST I, washing and distillation equipment, waxing machine TECMO), Refinery II (Gravure printing machine BOBST II and gluing machine Polytype BB 1280) and lines for the production of final products.

The final lunch took place in the canteen of AL INVEST, where the President of the Society Ing. Martin Špok thanked the guarantors for the preparation and implementation of the seminar and closed the seminar.